Advantages

![]() Real-time self-tracking of welds, no need to lay tracks, no manned programming and teaching

Real-time self-tracking of welds, no need to lay tracks, no manned programming and teaching

![]() Portable design, small size and light weight, convenient for on-site transfer

Portable design, small size and light weight, convenient for on-site transfer

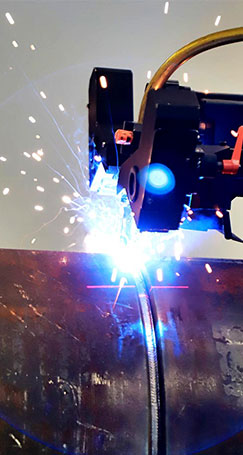

![]() Fixed pipes, robot crawling on the pipe, for both on-site and prefabricated operations

Fixed pipes, robot crawling on the pipe, for both on-site and prefabricated operations

![]() Two sets of laser tracking systems, for both upward and downward welding

Two sets of laser tracking systems, for both upward and downward welding

![]() Junior welders can be proficient in operation after only two weeks of training, reducing labor costs

Junior welders can be proficient in operation after only two weeks of training, reducing labor costs

![]() Welding process database records to ensure the smooth implementation of process requirements and reduce management costs

Welding process database records to ensure the smooth implementation of process requirements and reduce management costs

Application

Application scenarios: process pipelines of pipe gallery, buried pipelines, long-distance pipelines, thermal pipelines, etc.

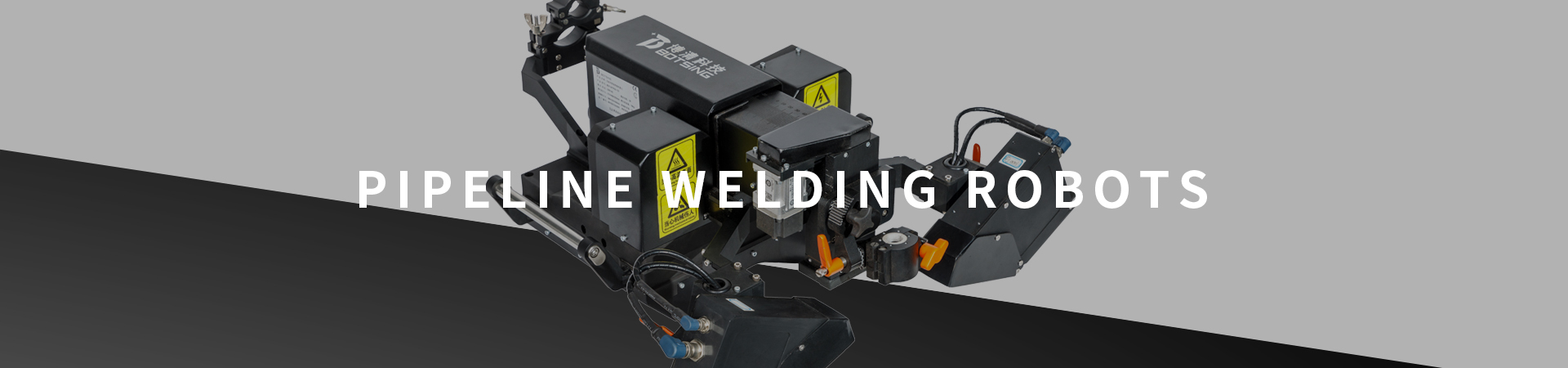

| BOT-WTP20-121 | |

| Dimensions | 552*570*255(mm) |

| Weight | 18kg |

| Maximum load | 50kg |

| Diameter of walking surface | 168mm-813mm |

| Chassis structure | Wheeled chassis |

| Welding torch position | Side torch |

| Number of laser tracking systems | 2 |

| Accuracy of laser tracking system | ±0.2mm |